Large organizations are increasingly operating in complex global markets, trying to keep up with the rapid pace of technological advancement while maintaining a competitive advantage. The need to adapt and innovate is clear. However, relying solely on internal sources of innovation—which may involve incentivizing employees, fostering intrapreneurship, and building dedicated R&D units, innovation labs, or incubators—can be time-consuming and costly.

As a solution to these challenges, more organizations are complementing their internal intelligence with external sources of innovation. This open innovation approach can take many forms, from crowdsourcing to broadcast and pyramid search, involving several different external sources.

Amongst these external sources, suppliers are shown to have a high potential for impacting innovation due to their existing relationship with the company—that is, their customer. With an intimate understanding of the company’s needs and supply chain and with mechanisms for collaborating already in place, suppliers are well-positioned to contribute to a company's innovation success.

In this article, we provide an overview of supplier innovation, tips for how to get started, and a best-practice example from one of Germany’s largest manufacturing firms. Read on to learn how to put this strategy into practice and turn your suppliers’ creativity, expertise, and resources into promising new solutions.

What is supplier innovation?

As the name suggests, supplier innovation is a business strategy in which a company actively collaborates with its suppliers to drive innovation and improve various aspects of its products, processes, or services. It is characterized by close partnerships and the exchange of knowledge, ideas, and technologies between a company and its suppliers.

This joint innovation approach is particularly common in industries where suppliers play a crucial role in a company's value chain, such as manufacturing, automotive, ICTs, and pharmaceuticals. It can lead to improved product quality, cost savings, and the ability to respond more effectively to market changes—making it an important innovation strategy to consider

Benefits of supplier collaboration

Leveraging supplier relationships for open innovation can offer many benefits and positively impact product development, cost management, and overall competitiveness. Here are some key benefits of supplier innovation:

- Access to specialized intelligence: Provide industry-specific knowledge and expertise that can lead to innovative solutions, improved product design, and cost-effective manufacturing processes.

Cost reduction: Lower operating costs, optimize processes, and improve resource allocation, resulting in higher margins and greater profitability.

Accelerate innovation: Speed up ideation and development cycles to bring offers to market at the right time and before the competition.

Quality improvement: Enhance product quality and consistency, reducing defects and ensuring high standards are met.

Competitive advantage: Develop new innovative ideas with a broader functionality scope, helping companies stand out in the market and meet changing customer demands.

Fill in the innovation gaps with suppliers

Collaborating with external suppliers is more than just adding extra brainpower and different ideas to the table. Suppliers can bring insights from both end customers and manufacturers. They have an outside perspective of the customers’ needs and the various aspects of the purchase decision that the manufacturer might not be exposed to—allowing them to identify blind spots, lost potential, and new opportunities.

Tips for effective supplier innovation

Leveraging external supplier know-how to foster innovation in a way that is both well-managed and mutually beneficial can be challenging. An analysis from consulting firm Oliver Wynman found that 80% of companies struggle to integrate their supplier base into the innovation process. Some of the obstacles companies face include fear of potential IP issues, lack of internal buy-in, mischaracterized supplier capabilities, and, generally, poor execution.

Fostering supplier innovation requires a deliberate and strategic approach that emphasizes collaboration, trust, and mutual benefit. Here are some best practice tips to consider when getting started with supplier innovation:

Supplier selection and evaluation

After assessing your organization’s needs and identifying potential suppliers who align with these needs, narrow down your selection based on each candidate’s quality, cost, innovation capabilities, and willingness to collaborate. Establish metrics of success and regularly evaluate supplier innovation performance regarding responsiveness and adherence to agreed-upon standards.

Align and define

From the start, it's essential to ensure strategic alignment between the organization and its suppliers. This step includes clearly defining the innovation objectives, roles, and responsibilities. A common understanding of everyone's duties and contributions directs focus, eliminates duplication of innovation efforts, and prevents confusion or possible tension.

Integrate suppliers early

Given that up to 70% of the overall lifecycle expenses of bringing a new product to market are determined during the design phase, collaboration early in the development timeline is likely to have a much bigger impact. Involving suppliers early in the innovation process allows for better alignment of goals and priorities, meaning that their input can have a greater impact on total lifecycle costs down the line.

Ensure a cultural fit

It is much easier to scale up and accelerate innovation when mutual trust, open communication, and a culture of collaboration are shared between you and your suppliers. A cultural fit should emphasize constructive conflict resolution, mutual risk-taking and reward-sharing, and agility. This leads to more reliable, sustainable, and productive partnerships than purely transactional relationships.

Manage intellectual property

Intellectual property rights are essential considerations in supplier innovation. Establish clear agreements regarding intellectual property ownership and protection. Define who owns the innovations created during collaborative projects and how they can be used. It is also critical to ensure that confidentiality and data security measures are in place to protect sensitive information.

Reward supplier innovation

Making your collaboration mutually beneficial by developing appropriate incentives helps encourage suppliers to proactively contribute to innovation, quality, and cost-efficiency initiatives. Due to the nature of the supplier-company relationship, there are many attractive incentives you can offer, including financial rewards, exclusive or extended contracts, co-development opportunities, and access to resources.

Success story: How DMG MORI drives supplier-driven innovation

DMG MORI, one of Germany's largest manufacturers of cutting machine tools, sharpened its competitive edge by integrating its suppliers into the innovation process using the ITONICS Innovation Operating System. DMG MORI involves its suppliers from the earliest development through to later design phases, where they can contribute with ideas for process and product innovation.

Since open innovation allows for more distributed and participatory innovation, the suppliers’ know-how is crucial in developing customer-oriented and competitive products for DMG MORI. To empower supplier innovation on a global scale with a geographically dispersed supplier base, DMG MORI opted for a digital solution that is collaborative, fully configurable, and easily scalable.

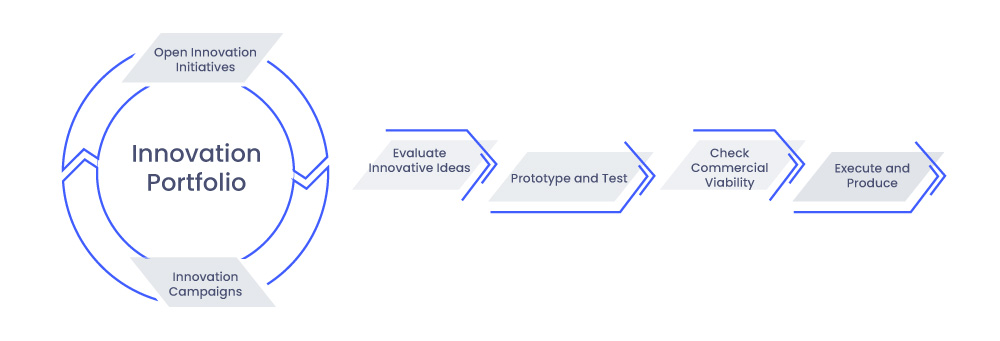

Powered by ITONICS, the DMG MORI Innovation Platform enables widespread engagement of suppliers across the company’s innovation campaigns and idea challenges. The centralized platform provides an engine for continuous idea management. External portals and templates allow suppliers to proactively add ideas for new products or services. Meanwhile, collaborative ratings, configurable phase-gate workflows, and dashboards make it easy for DMG MORI to prioritize and implement ideas.

DMG MORI’s process for fostering supplier innovation using ITONICS Ideation is as follows:

- Collect supplier ideas: Set up an open innovation campaign and engage suppliers to submit ideas for developing new innovations or enriching conceptualized innovations early in their development. Collect, categorize, and manage the entire ideas ecosystem in one central place.

- Evaluate ideas: Configure idea evaluation criteria to align with innovation objectives, including business relevance, strategic fit, and disruptive potential. Invite stakeholders and experts to rate the submitted ideas, prioritizing and refining the top-rated ideas before transferring them to the company’s innovation project portfolio.

- Prototyping: Under each project, create a prototype to test and validate the idea. Gather real-world customer feedback for improvements before full-scale development, reducing risk and optimizing resource allocation.

- Check commercial viability: Assess whether the innovation has the potential to be successful in the marketplace and generate a profit. This step includes creating a business case and financial projections while also considering factors like compliance, sustainability, and scalability.

- Start production: Before moving to production, refine the initial concept based on feedback, viability assessments, and market research. Effective planning, monitoring, and adaptation are crucial for successfully transitioning from ideation to production.

Your digital platform to manage supplier innovation

The ITONICS Innovation OS supports end-to-end supplier innovation. It systemizes your supplier relationship management to quickly identify the right suppliers to collaborate with, monitor and evaluate supplier performance, and scout for potential partners outside your network.

Use ITONICS Ideation to configure and launch multiple supplier innovation campaigns, improve supplier engagement, and build a culture of collaboration. Collect and manage ideas from outside your organization to amplify your innovation intelligence and increase the value of your innovation pipeline.

- Bring various stakeholders and experts on board to collaborate on innovation projects and challenges.

Collect ideas easily using best practice templates and move ideas systematically through custom phases-gate workflows.

Automatically tag, categorize, and relate ideas to identify synergies, remove duplication, and streamline decision-making.

Boost participation with in-system notifications, engagement and gamification features, and newsletters.

Configure custom idea evaluation criteria and invite stakeholders to rate ideas for further refinement and implementation.

The ITONICS Innovation OS links your ideas ecosystem with your strategic foresight activities and innovation portfolio. Creating a single point of truth for all your innovation intelligence and activities breaks down information silos and enables collaboration to help you better connect the dots between insights, ideas, and strategy realization.

Want to learn more about how ITONICS supports supplier innovation? Book a free demo with our experts and see for yourself!